20 years of successful company history

The history of ART begins in November 1999 in "Herrsching am Ammersee". Konrad Zürl, head of development for the German department of a Swedish company, decides to establish an independent company in order to be able to meet the demands (to respond to the requirements) of the market. It turns out relatively quickly that this estimation was correct and ART is going to develop into a globally known and recognised provider of optical tracking systems in the coming years.

Today, 20 years later, we look back with company founder Konrad Zürl and the current managing directors Armin Weiß and Ulrich Probost and also take a look into the future:

Konrad, how did you get the idea to found ART?

Konrad: We set up a small development department in the German office of the Swedish company to make the old Swedish tracking cameras real-time capable. Back then, this was important for virtual film and television studios. The parent company in Gothenburg had estimated the development effort to be quite small. However, we understood that it is not so easy to turn a VW Beetle into a Porsche by mounting wider tires. It was obvious to us that core parts of the tracking camera and the complete system had to be redeveloped. And Gothenburg complained more and more that it would be too expensive, that we were not allowed to hire more people (in order to accelerate the development) etc. For that reason, the managing director of the Herrsching office and I said: “Let's try it out ourselves and start our own company! It was actually an MBO, but we finally founded our own GmbH (ART) to create clear conditions. However, my colleague left after three months when a debt financing (venture capital) was unsuccessful. Then I had to manage the A.R.T. GmbH myself - and first of all I had to see how to get it financed.

What do you remember from the early days?

Konrad: In the beginning, one of the central problems was: Where do we (or I) get enough money to finance the development, the start of the company? Three components (it would be exaggerated to speak of pillars): 1. We were able to buy camera components from our former Swedish employer in Gothenburg and gradually replace them with our own components. Back then, we bought the tracking software algorithms (just like the Swedes), but we additionally had to program something. So, we were soon able to sell "our" first systems. 2. We could participate in an ongoing research project (Arvika) funded by the BMBF. 3. Privately I run into debts to the brink of ruin and put everything into the company. At that time even my parents charged their house as collateral for a loan. I actually had no doubt that ART, that our products, would be successful. I don't think I'm a fearful type and I always slept peacefully. The advantage of self-financing was that there was no external interference and that I didn't have to keep investors happy - this saves time in order to be able to concentrate on the essentials.

We operated economically even though the money often was tight. In the beginning it sometimes happened that I had to ask employees: If it is okay that half of the salary is not paid until the middle of the month?

Armin: As Konrad says, one question was most important: "How do we get money for the company?". We tried to get venture capital (VC), but the business model we presented was not well received at the time and was also formulated too cautiously so that nobody really wanted to invest in us. I remember a phone call to an investor who said to me, "How much do you want? Half a million? For that, I don’t even pick up a pen!"

What do you remember from the early days?

Konrad: In the beginning, one of the central problems was: Where do we (or I) get enough money to finance the development, the start of the company? Three components (it would be exaggerated to speak of pillars): 1. We were able to buy camera components from our former Swedish employer in Gothenburg and gradually replace them with our own components. Back then, we bought the tracking software algorithms (just like the Swedes), but we additionally had to program something. So, we were soon able to sell "our" first systems. 2. We could participate in an ongoing research project (Arvika) funded by the BMBF. 3. Privately I run into debts to the brink of ruin and put everything into the company. At that time even my parents charged their house as collateral for a loan. I actually had no doubt that ART, that our products, would be successful. I don't think I'm a fearful type and I always slept peacefully. The advantage of self-financing was that there was no external interference and that I didn't have to keep investors happy - this saves time in order to be able to concentrate on the essentials.

We operated economically even though the money often was tight. In the beginning it sometimes happened that I had to ask employees: If it is okay that half of the salary is not paid until the middle of the month?

Armin: As Konrad says, one question was most important: "How do we get money for the company?". We tried to get venture capital (VC), but the business model we presented was not well received at the time and was also formulated too cautiously so that nobody really wanted to invest in us. I remember a phone call to an investor who said to me, "How much do you want? Half a million? For that, I don’t even pick up a pen!"

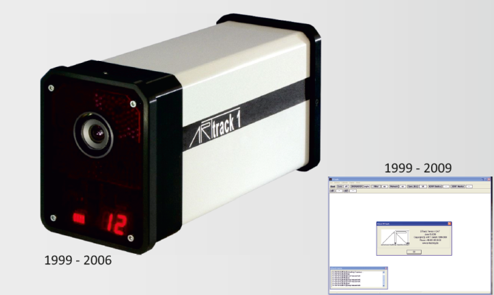

What was your first product?

Armin: Definitely ARTTRACK1 and DTrack1, a little later Flystick1. Some customers still use these products today and they do their job like on the first day. Then as now, the concept of offering optical tracking systems that are specially optimised for use in VR applications was perfect. It has taken the performance of tracking in VR to a new level.

Konrad: Obviously, ARTTRACK1 was as big as a toaster and as heavy as a brick, but it did and does its job. According to the old engineering saying, "form follows function".

You are a high-tech company based in Weilheim, why not in Munich?

Konrad: The German branch office of the Swedish head office was in Herrsching. We took over the employees and additionally the rented company premises in Herrsching. Later we considered to build or to buy our own company building, we decided to stay in the region so as not to lose the employees. Because employees are the most important "capital" of the company. However, part of the workforce has always come from Munich - and they are not thrilled about Weilheim. So, some of them have changed to Munich-based companies. But many, like myself, enjoy the great surroundings around Weilheim for activities such as cycling or hiking.

Armin: I would like to amplify that currently almost half of the employees come from Weilheim or the surrounding area. And people like to move from large cities into a rural environment when they become parents.

Do you remember a special moment with a customer?

Armin: Still in my mind is my first contact with a possible sales partner in Korea. For me, a personal relationship is very important, never just a business connection. During the conversation I asked him what his hobbies are. He looked at me angrily and answered with a scowl: "Working is my hobby!"

Is there anything you are really proud of?

Konrad: That doesn't exactly answer the question, but it's important to me. Among other things, ISO9001 certification carved out that at ART employees are most important in addition to customers. A very nice side effect! Beside that, it is nice that the growth of ART only is "organic", i.e. little withdrawal of profits, no bank debt and purely self-financed growth.

Armin: I am proud of the growth of the company without outside capital and that we operate it profitably most of its history. Beyond that, colleagues like to come to work every morning (at least most of them).

Konrad: And what I am proud of is that it is important for us at ART to socialise in our spare time such as the annual company outings to the mountains or at special events for the 10th or now the 20th anniversary. I like to remember 2016, when we were able to distribute a bonus to the employees that was even higher than that of a major Bavarian automobile manufacturer.

Your products are known as "high-priced": is that a problem for you or your sales department?

Armin: Definitely! Very few customers are familiar with the true saying "who buys cheap, buys twice". You always have to argue and sometimes accept that customers buy other companies' products. Especially when younger people or controllers contribute their opinions.

What is important to you in your company?

Armin: Especially the sustainable development of our company, i.e. no growth as an “end in itself” or just to make more profit is very important to me. Furthermore, to me it is important that we are committed in research and development. I like that. It's more fun too. In that way we get many innovations.

Konrad: From the very first funded R&D projects were very important to us. On the one hand we receive grants for research costs on the other hand we get close in contact with users. This is even more important because we learn the needs of customers.

What have been the milestones in the past 20 years?

Konrad: When our first own camera worked with our software for the first time. It was a great feeling. And the first time to be in the black is probably a huge success for any daring company.

Armin: Yes, that's right. At that point we had the certain feeling "now it's working". As milestones, I would also like to mention the products with which we have often succeeded in setting standards for the VR market: e.g. the first Flystick, Fingertracking, cameras for closed CAVEs, or the SMARTTRACK, but also the sophisticated functionality of our DTrack software.

Konrad: When we had the single cable solution for our cameras ARTTRACK5, TRACKPACK/E and now also for SMARTTRACK3 in the market, these were also important milestones.

Ulrich: We shouldn't forget the recent successes. VERPOSE, our technology for camera-based tracking of assembly tools, received first prize last year for the best assembly idea. In addition, VERPOSE is already very promising in the assembly industry in use. In addition to VERPOSE, CAPTA is also a great success. This is our markerless tracking solution. CAPTA offers extremely fast, initial object recognition. Some companies are amazed. (smiles)

Have customers and their needs changed in the past 20 years?

Armin: Yes, definitely that too! VR used to be the “cutting edge” of industrial development, so everyone wanted best products. Today, many people know the VR technology only out of the gaming corner and they only want to play around with investments under 1000 euros. That has already changed the market.

Where is ART going to be in the next 20 years?

Konrad: I'm already there - retired. (laughs) Armin and Ulrich should answer that.

Armin: I remember an event from our early years: A potential business partner (we didn’t have a business connection later) visited us. After an introduction and tour of the company, he asked me: "And where will you see ART in 5 years?". He overwhelmed me with this question. I thought: "I would be happy if we will survive next year."

Ulrich: I think, first priority is to continue the company in a stable and solid manner. We have many clever and well-trained colleagues who help to improve products and open up completely new fields of application. This will make it possible to position the company more broadly and therefore more securely because of these new markets. This means that the perceived dependence on VR is gradually reduced, but not abandoned. And then we look forward to the 40th anniversary! (smiles)

Armin: Close contact to our customers is and remains very important. For example, with our TECHDAYs. We invite selected customers and partners to this event, which we have held for the second time this year, to show them our latest technology developments. The feedback and the intensive interaction with the customers help us with the goal-oriented development of new technologies, so that the requirements of the customers can be fulfilled in the best possible way. At this year's TECHDAY we presented a successful collaboration.

Ulrich: And it will also apply to the future that we want to remain a good and far-sighted employer here in the region. For example, we have been working and producing in a sustainable manner. We rely on local suppliers, high-quality components and we are always looking for environmentally sustainable solutions.

On balance our company has a very good reputation. ART products are known for their excellent quality worldwide. At the same time, ART is known for "they can make it possible". That means, customer problems are our challenges. Of course, we like to realise the customer's requirements in the optimum manner over the next few decades.

Thank you for offering an interesting insight into the company's history. We wish you further success for the next 20 years!

The interview was conducted by ART's Marketing: Kristina Gabriel and Petra Kluge.