Production processes are complex and error-prone. So for a most efficient and smooth course you need to survey and control your work steps thoroughly. We at Advanced Realtime Tracking offer diverse technologies to control and optimize these processes:

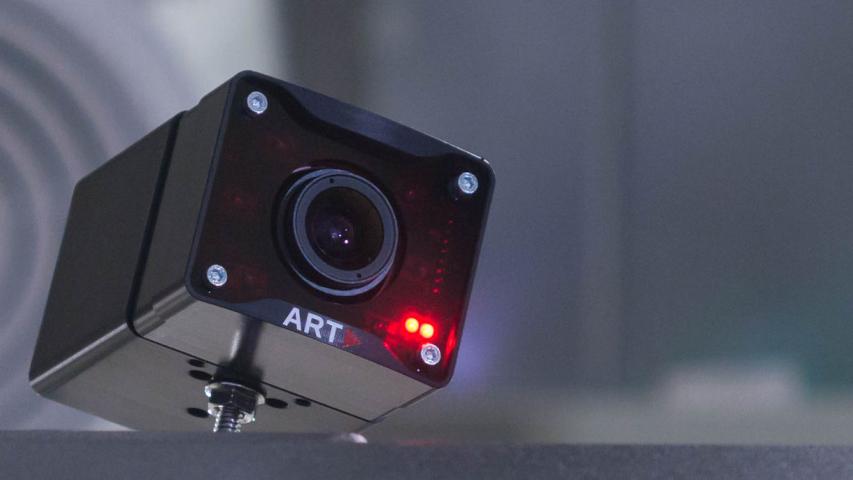

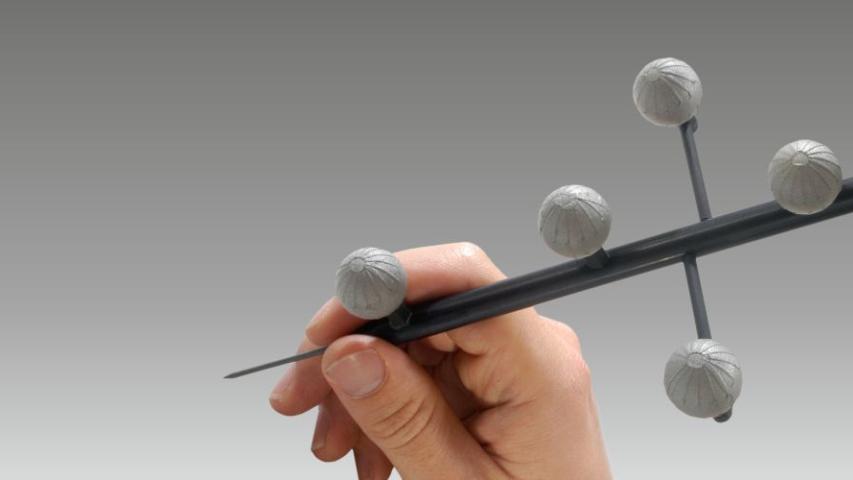

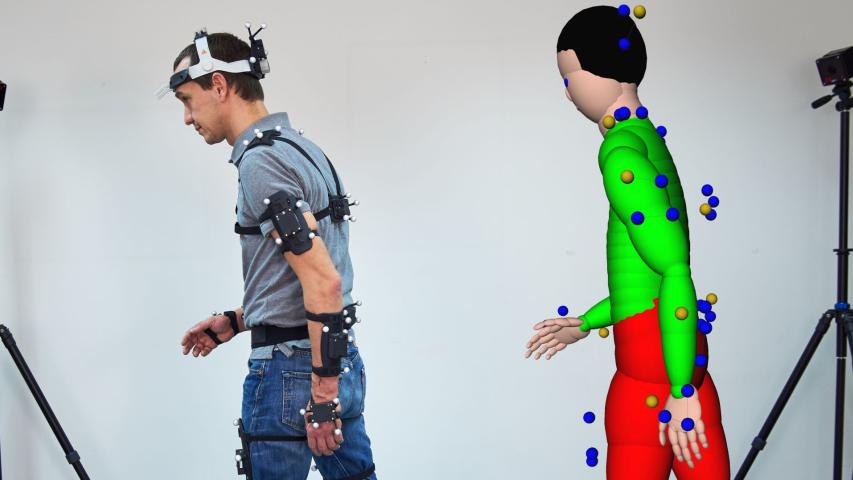

Our marker-based optical tracking systems track the position of a tool. For instance, it determines where the tool is being used in the assembly process. A seperate application software notes the correct positions of the tool on the work schedule.

Ou markerless object detection solution CAPTA works with a camera system that views the assembly area. It detects and documents the position of a tool and tracks it. The best part of all: CAPTA also identifies work points even in hidden places.

Our localisation solution VERPOSE is a camera based system for hand-held assembly tools. Its intelligent image analysis software detects pre-defined assembly positions instantly. Even more: The application software can ensure that assembly sequences will be correctly performed.

Our three technologies can also be combined! As you can see: You can optimize your production steps and avoid mistakes with our sophisticated technologies!

Improved process assurance and cost savings through:

- Higher process reliability and minimization of errors in the assembly process.

- Reduction of rework rate.

- Prevention of defects and thus greater flexibility of time for the worker.

- The test setup is straightforward. Quick and easy training.

- The modular systems can be adapted to a wide range of industrial requirements.