Do you already benefit from Tool Tracking systems in your production process? Are you aware of how valuable they can be, because they can optimize your assembly sequences and thus save you time and money?

Currently we offer two approaches for Tool Tracking solutions:

1. ART‘s solution with DTRACK - Marker-based tool tracking.

For table-like assembly situations ART provides an industrial version of its well-known DTRACK. Our DTRACK solution identifies the critical positions of the handheld tool by using reflection-based triangulation and provides accurate 6DOF output from any tool, or even from the assembly location.

A small passive target on the tool enables to track any assembly device with the compact ART optical tracking system.

Moreover, DTRACK can monitor several devices at the same time in the same area.

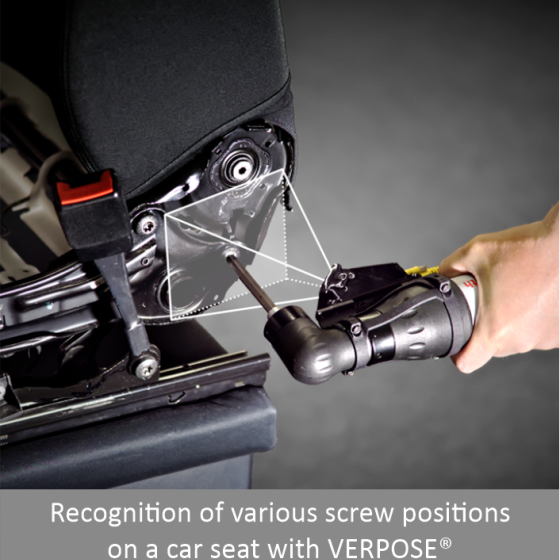

2. ART‘s solution with VERPOSE® - Easy-to-use image recognition.

The small and robust VERPOSE® camera mounted on the tool detects critical assembly screw positions. It enables preventing assembly mistakes by controlling and identifiying the sequence and screw positions. By using an AI software, the screw positions, trained in a short setup process, will then be able to recognize accurately and robustly.

Our cableless VERPOSE® version VERPOSE/TI is closely interacting with the tool to achieve maximum performance in a compact shape.

Tool Tracking enhancement

In our latest version we embedded some exciting, helpful features:

- Auto-adjust Tool Tip - Automatically adapts to socket length for greater precision

- Expanded Tool Library - New tools added continually for broader compatibility

- New Integrated Tool Targets - Unlock even more tracking possibilities.

Use Case

Detecting and eliminating paintwork anomalies of car parts in the production process

In cooperation with our partner Extend3D from Munich we achieved a fantastic solution by combining ART Tool Tracking with Extend3D laser projection:

In this example we look at a production line of a car manufacturer, where car parts or complete car bodies just have been painted and then have to be controlled for any anomalies or unintended features such as nibs, craters, etc..:

- In a first step, areas that may need to be reworked are identified by an automated inspection.

- With the help of Extend3D's dynamic laser projection, CAD data, work instructions, 3D measurement protocols or other important information can be displayed correctly and precisely, directly on the workpiece - even while it is moving. Thus, the worker can see exactly where he needs to attach which component or what he needs to touch up (in our example, paintwork areas to be touched up are shown on the vehicle part).

- The ART tool tracking can then be used to determine whether the right action was carried out with the right tool in the right position (in this case the painting process).

- By being able to display information about the work steps, the system supports the worker and makes his work considerably easier. The combined ART/Extend3D solution achieves a time-saving, total defect control!

"ART's localization expertise together with our in-depth knowledge of dynamic projection solutions has opened up new possibilities: Through the combination of 3D visualization with tool tracking, we have achieved for the first time a solution that seamlessly and bi-directionally links analogue and digital elements with a spatial reference to the work item. This digitization also makes a 100% digital twin possible for processes comprising manual work steps." Dr. Peter Keitler, CEO of Extend3D

System installation

- Tracking system: SMARTTRACK3/M or ARTTRACK6/M system by ART

- ART markerless tracking solution CAPTA

- Laser projection system: WERKLICHT Pro SM by Extend3D

The systems are firmly integrated into the working environment and fully automated via an OPC UA interface. Depending on the customer’s requirements, the numbers of devices have to be adapted.

Contact us to get a detailed consulting.

Videos:

Tool Tracking by ART and Extend3D

Dynamische Laserprojektion, Extend3D (deutsch)

Marker-based Tool Tracking - ART's solution with DTRACK (SMARTTRACK3/M)

Easy-to-use image recognition. ART's solution with VERPOSE